NOC from concerned authorities of Electricity and Gas suppliers in case of loan disbursement

NOC from concerned authorities of Electricity and Gas suppliers in case of loan disbursement Entrepreneurship Support Fund (ESF)

Entrepreneurship Support Fund (ESF) Startup Fund Bangladesh Bank

Startup Fund Bangladesh Bank LEED Certification Procedures for Industrial Green Building

LEED Certification Procedures for Industrial Green Building Bangladesh: A New Horizon For Investment

Bangladesh: A New Horizon For Investment Focus on raising private sector investment for GDP growth

Focus on raising private sector investment for GDP growth Duty Free Quota Free export items to China

Duty Free Quota Free export items to China Bangladesh’s $50bn RMG export target

Bangladesh’s $50bn RMG export target Export of jute stick charcoal fetches Tk 140m from China

Export of jute stick charcoal fetches Tk 140m from China Investment scenario of Bangladesh

Investment scenario of Bangladesh

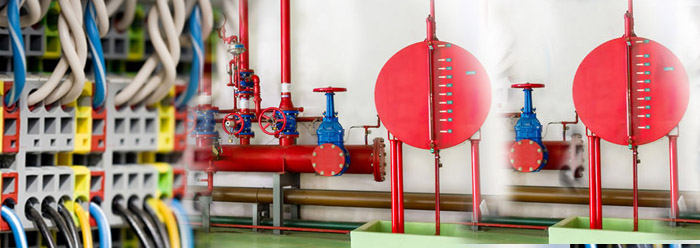

Mechanical, electrical and plumbing designing

MEP (Mechanical, Electrical, and Plumbing) systems play a vital role in the design and operation of energy-efficient and sustainable green industrial projects. Here's how MEP contributes to these objectives:

Mechanical Systems

Heating, Ventilation, and Air Conditioning (HVAC):

- Energy Efficiency: Utilizing high-efficiency HVAC systems, variable speed drives, and energy recovery ventilation can significantly reduce energy consumption.

- Smart Controls: Implementing advanced control systems and building automation can optimize HVAC operations, adjusting settings based on occupancy and external weather conditions.

- Geothermal Systems: Using geothermal heat pumps can harness the stable underground temperatures for heating and cooling, reducing reliance on fossil fuels.

Renewable Energy Integration:

- Solar Thermal Systems: Solar panels can be used for water heating, reducing the need for conventional energy sources.

- Combined Heat and Power (CHP): Integrating CHP systems can improve overall energy efficiency by utilizing waste heat for heating purposes.

Efficient Equipment:

- High-Efficiency Motors and Compressors: Implementing energy-efficient motors and equipment can reduce the overall energy demand of the facility.

Electrical Systems:

Lighting:

- LED Lighting: LED lights consume less energy and have a longer lifespan compared to traditional lighting options.

- Daylighting: Designing buildings to maximize natural light reduces the need for artificial lighting during the day.

- Smart Lighting Controls: Implementing occupancy sensors and daylight harvesting systems can optimize lighting usage and save energy.

Power Distribution:

- Energy Monitoring and Management Systems: Advanced metering infrastructure and energy management systems enable real-time monitoring and control of energy usage, identifying opportunities for energy savings.

- Renewable Energy Sources: Integrating photovoltaic (PV) systems and wind turbines can provide sustainable, renewable energy sources for the building.

Backup Power Systems:

- Battery Storage: Using battery storage systems can store excess renewable energy generated on-site for use during peak demand periods or outages.

Plumbing Systems:

Water Efficiency:

- Low-Flow Fixtures: Installing low-flow toilets, faucets, and showerheads can significantly reduce water consumption.

- Sensor-Activated Fixtures: Implementing sensor-activated fixtures ensures water is only used when necessary, minimizing wastage.

Water Reuse and Recycling:

- Greywater Systems: Greywater recycling systems can treat and reuse water from sinks, showers, and washing machines for irrigation and flushing toilets.

- Rainwater Harvesting: Capturing and storing rainwater for non-potable uses can reduce the demand on municipal water supplies.

Efficient Water Heating:

- Tankless Water Heaters: Tankless (on-demand) water heaters provide hot water only when needed, reducing energy usage compared to traditional tank water heaters.

- Solar Water Heaters: Utilizing solar energy for water heating can further enhance the sustainability of the plumbing system.

MEP design is important for design decision-making, accurate documentation, performance and cost-estimation, construction planning, managing and operating the resulting facility.

01. Our MEP activities:

The consultant responsibilities are detailed below for all the Electro Mechanical design services:

-

Requirement gathering

- Necessary inputs for the design will be gathered from clients.

- The input checklist will be shared by us with the client or project managers

- The client shall share the specific information if it has to be considered on the design (information included like preferences in equipment, company specific standards, any buyer specific standards, integrating existing system, future expansion provisions etc.).

- The client, users, architect, and other team members are responsible to provide the inputs to initiate the design activity.

- Number of site meeting is limited to one by the engineer/consultant.

-

Conceptual design

- Providing concept level design in PDF document. This includes the overall system capacity, major equipment capacities & configurations, tentative locations, cost-benefit analysis for the proposed equipment, type of material specification.

- Presentation of the overall concept to client technical team

- The client shall review the concept and confirm the inputs & assumptions, provide the confirmation on the proposed systems & equipment, provide and provide acceptance to consultant to proceed with detailed calculation.

- Number of meeting is limited to maximum of two by the engineer/consultant.

-

Detailed system design

- Upon receipt of approved concept design, the consultant will start the detailed system drawings.

- Providing DSD in AutoCAD. This includes the Schematic drawings, system layout, sectional drawings, and typical details

- Architect & other team members should review the drawings to check if it the layout is conflicts with other layouts of pipes etc.

- Architect & Client shall provide final confirmation on the layout to prevent rework

- Number of meeting is limited to maximum of two by the engineer/consultant.

-

Preparation of BOQ & Specification

- Upon receipt of approved Tender drawings, the Consultant will start the preparation of BOQ & Specification

- The BOQ & Specification will be provided for the proposed system and as per the drawings.

- The Contractor is responsible to ensure that all the equipment and materials are added to the BOQ in coordinating the drawings & BOQ and need to provide comprehensive proposal.

-

Technical Evaluation vendor submittals

- All the necessary technical documents should be collected from the bidders for technical evaluation.

- The Client’s procurement team will co-ordinate and obtain the technical documents & submittals from the bidders and submit to Consultant for technical evaluation.

- The Consultant will provide technical comparison to Client for further processing and work order

- Number of meeting is limited to maximum of two by the Engineer/Consultant.

-

Construction drawings

- Upon receipt of the work order from Clients, the Contractor will provide the detailed Construction & shop drawing for Consultant’s approval.

- The vendor will provide the final bill of quantities as per the Construction drawings and share with Consultants.

- Consultant will review the BOQ and will provide technical approval.

- The Client will release the LC & procurement orders based on the final bill of quantities submitted by the vendor.

-

Final Inspection of Execution

- Client shall engage their Project Managers & Supervisors for project execution as per the schedule & monitor the installation quality.

- Number of site visit meeting is limited to maximum of three by the Engineer/Consultant.

2. List of services

The following are the list of Electro-mechanical items included in our scope of services

- Electrical Systems

- Fire Protection (Hydrant & Sprinkler system)

- Fire Alarm System

- Air Conditioning System

- Ventilation System

- Plumbing and sanitary system

- Rain water harvesting system

- Air Compressor System

- Steam piping system

- CCTV & Public addressing system

- Building Management System

3. Requirements from Client

The following are the list of items required from Client

- Architectural drawings

- Structural drawings

- Landscape design

- Process layout with equipment & machines & detailed specification

- IT networking Data, Voice

4. List of Deliverable by the Client

The following are the list of deliverables will be provided by the MEP Consultant

- MEP Concept Design Documents

- MEP Tender Design Drawings

- MEP Bill of Quantities with Specification

- MEP Vendor Technical Evaluation reports

- MEP installation inspection reports at the time of final inspection

Integration and Coordination:

- Building Information Modeling (BIM): BIM can be used to design and manage MEP systems more efficiently, allowing for better coordination and integration of all building systems.

- Commissioning and Maintenance: Regular commissioning and maintenance of MEP systems ensure they operate efficiently and continue to meet sustainability goals.

Benefits of MEP in Green Industrial Projects:

- Reduced Operational Costs: Energy-efficient MEP systems lower utility bills and maintenance costs.

- Enhanced Environmental Performance: Sustainable MEP systems reduce the carbon footprint and overall environmental impact of the building.

- Improved Occupant Comfort and Health: Efficient HVAC systems ensure good indoor air quality and comfortable temperatures, enhancing occupant well-being.

- Regulatory Compliance: Adhering to sustainability standards and certifications like LEED ensures compliance with environmental regulations and standards.

Incorporating efficient MEP systems in green industrial projects is crucial for achieving sustainability goals, reducing environmental impact, and ensuring long-term operational efficiency.